Shenzhen Magnetic Cube Technology Co., Ltd.(MCT) has more than 20 years of experience in manufacturing custom inductors. It was officially registered and established in Shenzhen in 2013. In the same year, Magnetic Cube Technology (Hong Kong) Co., Ltd. was established. We are a electronic component company specializing in the design, production and sales of various inductors and coils. Our company has 3 workshops and 6 production lines. The company covers an area of 1200 square meters with annual sales of $3.57 million. The company's main products are high-power inductors and magnetic core material, which are mainly used in computer motherboards, video cards and peripheral products (PDA, NOTE BOOK, LED, VGA, POWER SUPPLY, etc.), communication products (telephone, mobile phone, network communication, etc.) and consumer electronics components products (digital cameras, electronic toys, etc.). Looking forward to cooperating with you!

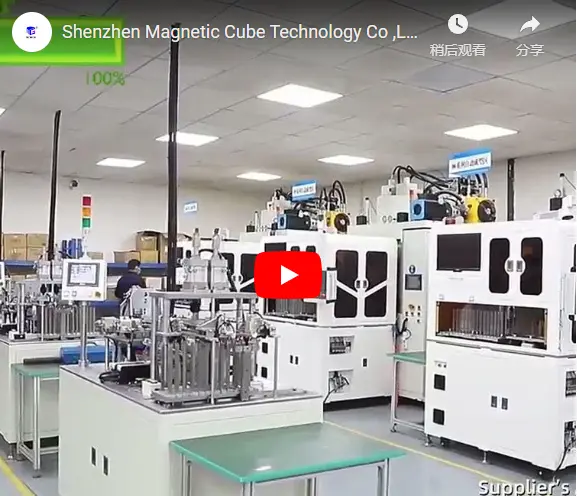

Magnetic Cube boasts three production workshops and six production lines, ensuring efficient and high-quality output. Our professional 8-member R&D team is dedicated to innovation and excellence. We have earned four international certifications, demonstrating our commitment to global standards. Plus, our customer service is available 24/7, reflecting our dedication to customer satisfaction.

At Shenzhen Magnetic Cube Technology Co., Ltd., quality control is at the heart of our operations. We employ rigorous testing and inspection processes at every stage of production to ensure our inductive charging components meet the highest standards. Our commitment to quality is unwavering, as we believe it is the cornerstone of customer satisfaction and trust. Trust Magnetic Cube, where quality is not just a goal, but a guarantee.