A Magnetic Core is a device used for storing and transforming electromagnetic energy. Made primarily of iron or other magnetic materials, it is widely used in power converters, electric motors, inductors, and other electronic devices, serving to enhance energy efficiency and stabilize current.

Magnetic cores are an integral part of many custom inductor designs, as they help enhance the inductance and magnetic field strength. Here is some specific information about magnetic cores:

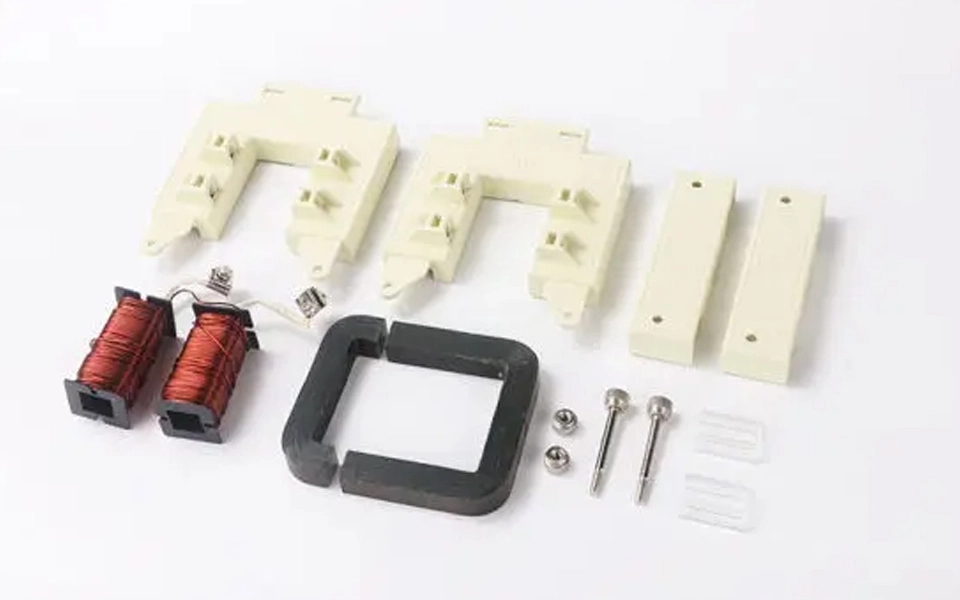

Types of Magnetic Cores: There are various types of magnetic cores used in inductors, including ferrite cores, powdered iron cores, laminated cores, and toroidal cores. Each type has its own unique properties and is suitable for different applications.

Ferrite Cores: Ferrite cores are made from a ceramic material composed of iron oxide and other metal oxides. They have high magnetic permeability and are commonly used in high-frequency applications due to their low losses and excellent magnetic properties at high frequencies.

Powdered Iron Cores: Powdered iron cores are made by compressing iron powder into a desired shape. They have high magnetic permeability and are often used in power applications due to their ability to handle high currents and high magnetic flux densities.

Laminated Cores: Laminated cores are made by stacking thin layers of magnetic material, such as silicon steel, to reduce eddy current losses. They are commonly used in low-frequency applications where low core losses are important.

Toroidal Cores: Toroidal cores are ring-shaped cores with a hole in the center. They provide a closed magnetic circuit, resulting in low magnetic leakage and high inductance. Toroidal cores are often used in applications where compact size and high efficiency are required.

Core Materials: The choice of core material depends on factors such as frequency range, power handling capacity, and desired performance characteristics. Different core materials have different saturation levels, temperature stability, and frequency response.

Core Losses: Magnetic cores can experience losses due to hysteresis and eddy currents. Hysteresis losses occur when the magnetic field is repeatedly reversed, while eddy current losses occur due to circulating currents induced in the core material. Minimizing core losses is important to improve the efficiency and performance of the inductor.

Core Selection: Selecting this inductance component involves considering factors such as the required inductance value, operating frequency, current handling capacity, temperature stability, and size constraints. Manufacturers provide datasheets and application notes to assist in selecting the appropriate core for a specific inductor design.

Selecting a Magnetic Core involves several factors:

1. Material: The core material determines the magnetic properties. Common materials include iron, silicon steel, nickel-iron, and ferrite.

2. Size and Shape: The core’s size and shape affect its inductance and power handling capabilities.

3. Frequency Range: Different core materials perform better at different frequencies.

Power Handling: The core must be able to handle the power level of the application.

4. Cost: The price of the these electric circuit components can vary greatly, so it’s important to balance cost with performance requirements.

Remember, the best magnetic core for your application depends on your specific requirements.

The manufacturing process of magnetic cores involves several steps, each of which is crucial to the performance of the final product. Here’s a general overview of the process:

Material Selection: The first step is to choose the right material for the core. This could be a type of metal, such as iron, or a ferrite compound. The choice of material will depend on the intended use of the core, as different materials have different magnetic properties.

Powder Preparation: The chosen material is then ground into a fine powder. This powder is often mixed with a binder to help it hold its shape in the later stages of the process.

Shaping: The powder is then shaped into the desired form. This is usually done by pressing the powder into a mold under high pressure. The shape of the mold will determine the shape of the final core.

Sintering: The shaped core is then heated in a process called sintering. This causes the particles of the material to bond together, forming a solid mass. The sintering process also helps to align the magnetic domains within the material, enhancing its magnetic properties.

Cooling: After sintering, the core is allowed to cool slowly. This helps to prevent cracks and other defects from forming in the material.

Finishing: The cooled core is then finished to the desired specifications. This may involve grinding or machining the core to achieve a precise size or shape, or applying a coating to protect the core from corrosion.

Testing: The final step is to test the core to ensure it meets the required performance standards. This may involve measuring the core’s magnetic properties, such as its permeability or coercivity.

It’s important to note that the exact process can vary depending on the type of magnetic core being produced and the specific requirements of the application.

wechat / phone

0755-23018051