>>Material Properties

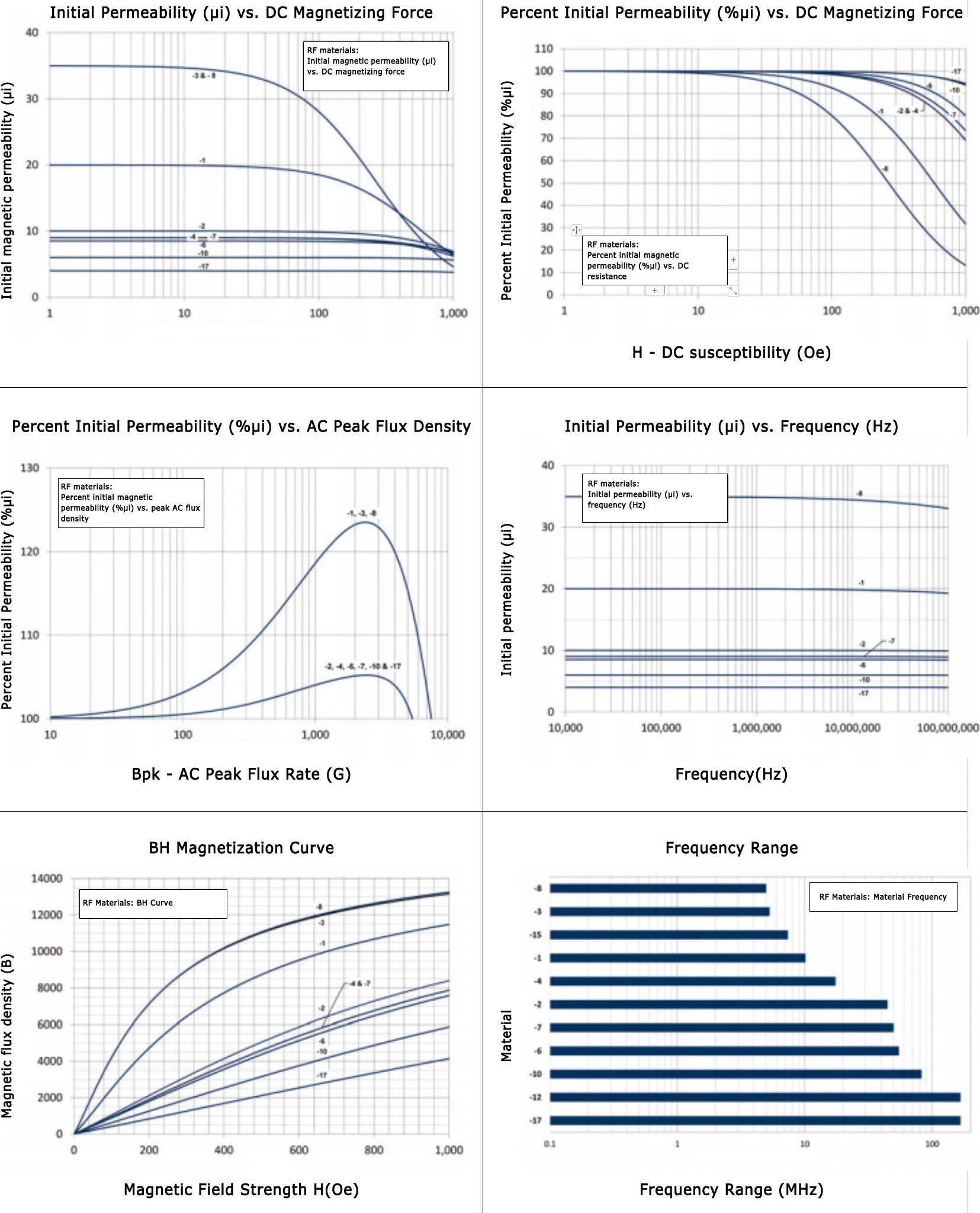

| Material Code | Magnetic Permeability Reference | Typical AL Tolerance (%) | Refer to Powder Type | Magnetic Permeability Temperature Coefficient (+ppm/C°) | Density gm/cm³ | Maximum Frequency (MHz) | Relative Cost* | Coating Color | Product Group RF |

| 0 | 1 | N/A | Phenolic Resin | N/A | N/A | N/A | 1.3 | Brown/Brown | √ |

| -1 | 20 | ±10 | Carbonyl Iron Powder | 280 | 6.4 | 10 | 3.8 | Blue/Transparent | √ |

| -2 | 10 | ±5 | Carbonyl Iron Powder | 95 | 5 | 45 | 2.2 | Red/Transparent | √ |

| -3 | 32 | ±10 | Carbonyl Iron Powder | 255 | 6.5 | 5 | 3.3 | Gray/Transparent | √ |

| -6 | 8.5 | ±5 | Carbonyl Iron Powder | 35 | 5 | 55 | 3.6 | Yellow/Transparent | √ |

| -7 | 9 | ±5 | Carbonyl Iron Powder | 30 | 5 | 50 | 3 | White/Transparent | √ |

| -8 | 35 | ±10 | Carbonyl Iron Powder | 255 | 6.5 | 5 | 3.1 | Yellow/Red | √ |

| -10 | 6 | ±5 | Carbonyl Iron Powder | 150 | 4.9 | 83 | 5.5 | Black/Transparent | √ |

| -14 | 14 | ±10 | Carbonyl Iron Powder | 150 | 5.2 | 20 | 2.8 | Black/Red | |

| -15 | 25 | ±10 | Carbonyl Iron Powder | 190 | 6.4 | 7 | 3.4 | Red/White | √ |

| -17 | 4 | ±5 | Carbonyl Iron Powder | 50 | 4.8 | 170 | 3.5 | Blue/Yellow | √ |

>>Material Information

The material is a widely used carbonyl iron mixture. High Q will still be provided up to 40MHz and is popular for amateur radio (HAM) and various other communications applications. They are also available for medium-band transformers in the frequency range 200~400MHz.

The material is annealed carbonyl iron, which provides the highest carbonyl permeability. They are available for high frequency applications below 1MHz, as well as the widest bandwidth transformers covering the typical range of 50 to 500MHz.

This material is carbonyl iron with high-frequency characteristics, and its high Q value reaches 150MHz. It is usually used in cable TV parts and can also be used to produce medium-band transformers of 400~700MHz.

This is a non-magnetic material. It provides a physical winding support for winding air core coils. It has excellent temperature stability and a high Q value that can reach the highest frequency. It is also suitable for medium-band transformers with typical frequency ranges between 600MHz and 1GHz.

The material's low permeability will result in lower operating AC flux densities than other materials without additional gap losses. -14 material is similar to -2 material and has higher magnetic permeability.

>>Materials Magnetic Powder Core Performance Index

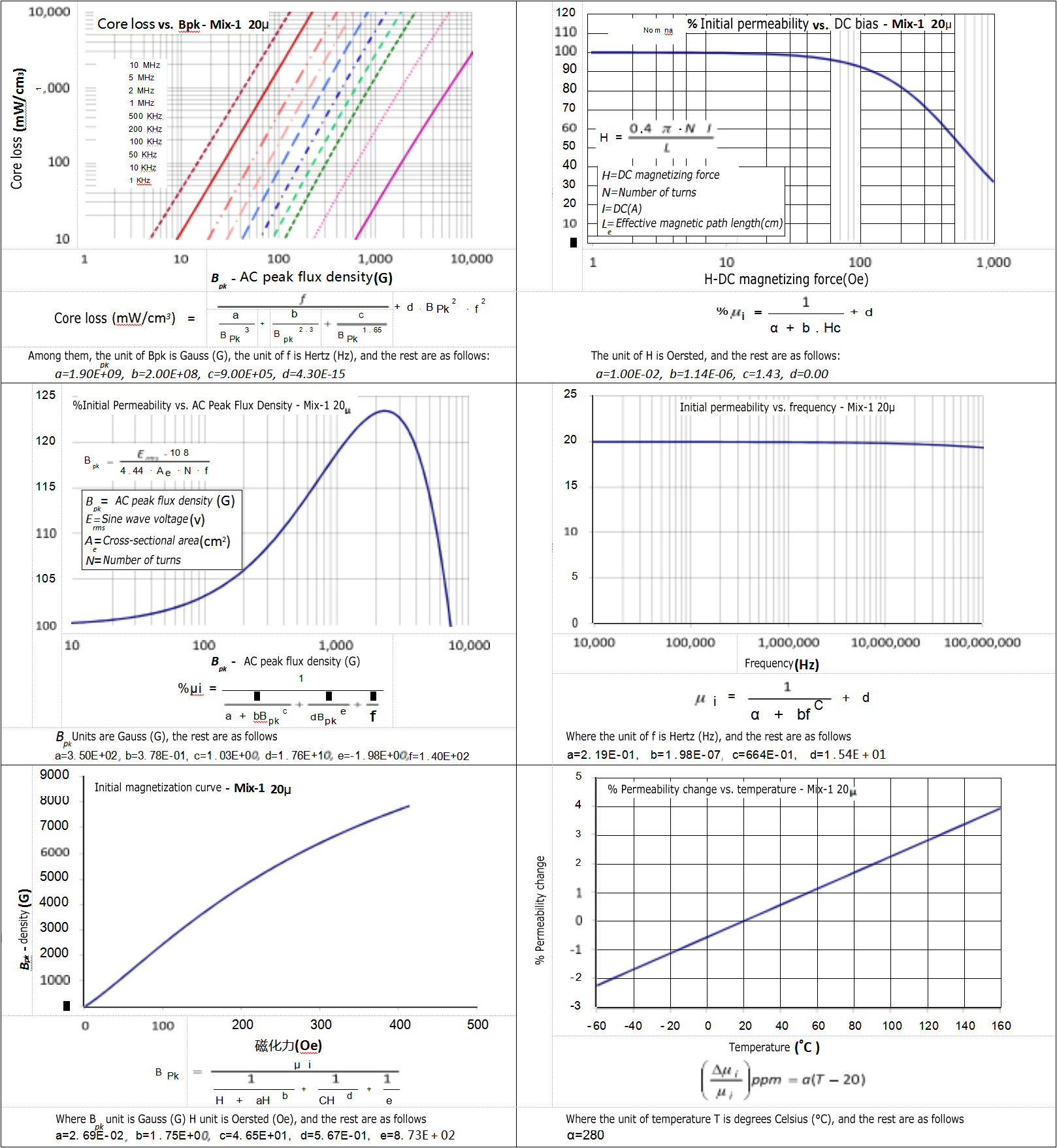

Material -1 is annealed carbonyl iron and provides the highest carbonyl permeability. Material No. -1 is suitable for high frequency applications below 1MHz and can also be used in the widest frequency band transformers, with typical coverage between 50~500MHz.

| Mix: | -1 |

| μ i (reference value) | 20 |

color | blue/transparent |

| density | 6.4 g/cm³ |

| Bsat | 17.5kG |

Core loss (100kHz, 140g) | 31 mW/cm³ (nom) 36 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 82.2% (nom) 78.0% (min) |

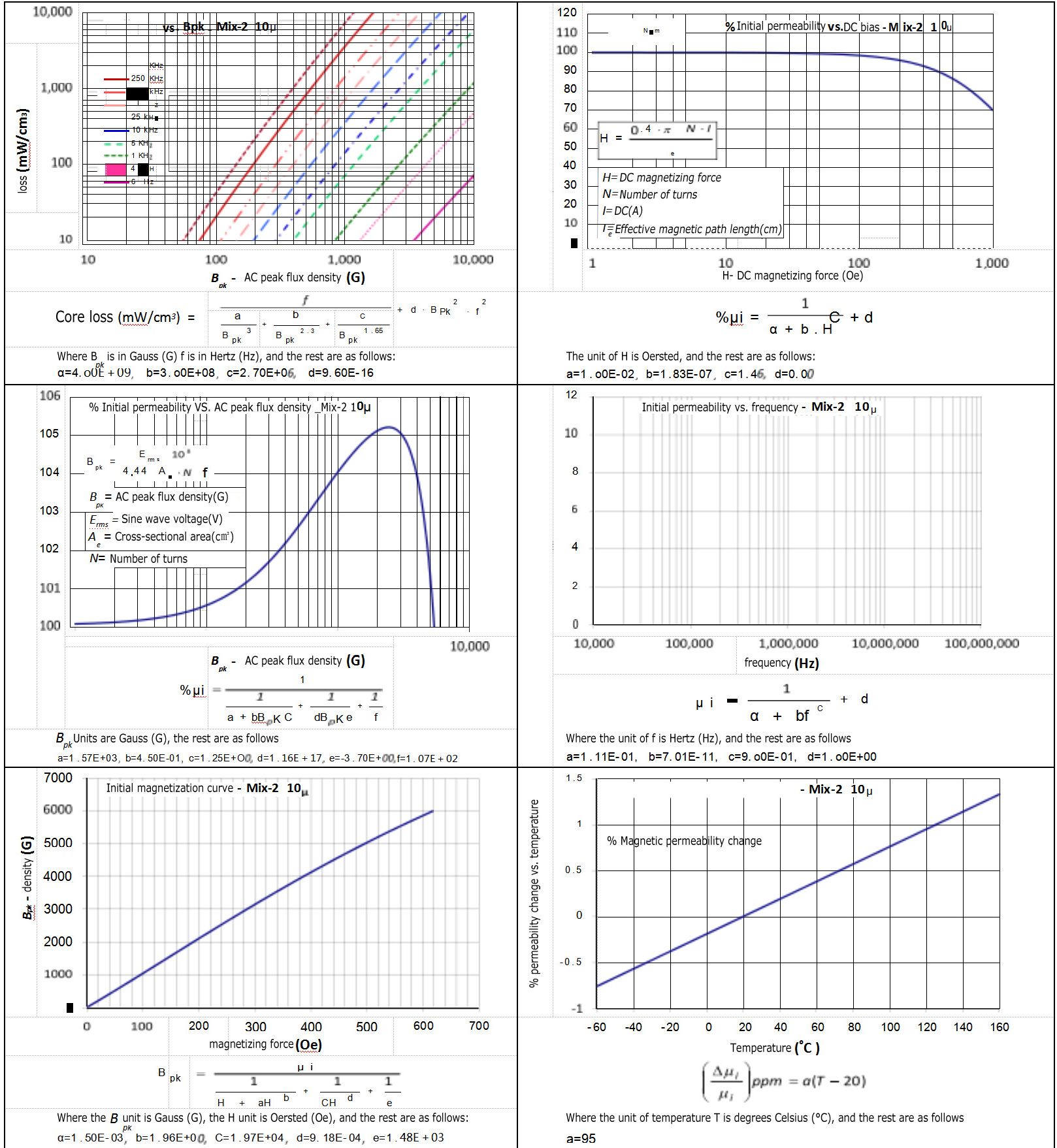

Material No. 2 is a carbonyl iron mixture and is widely used. Its high Q value is up to 40MHz, making it popular for amateur radio and various other communications applications. Material No. 2 can also be used for medium-band transformers in the frequency range 200~400MHz. The material's low permeability characteristics will result in lower operating AC flux densities than other materials without additional gap losses. If higher magnetic permeability is required, consider using -14 material.

| Mix: | -2 |

i (reference value) | 10 |

color | red/transparent |

density | 5.0 g/cm³ |

Bsat | 14.8kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 95.9% (nom) 94.8% (min) |

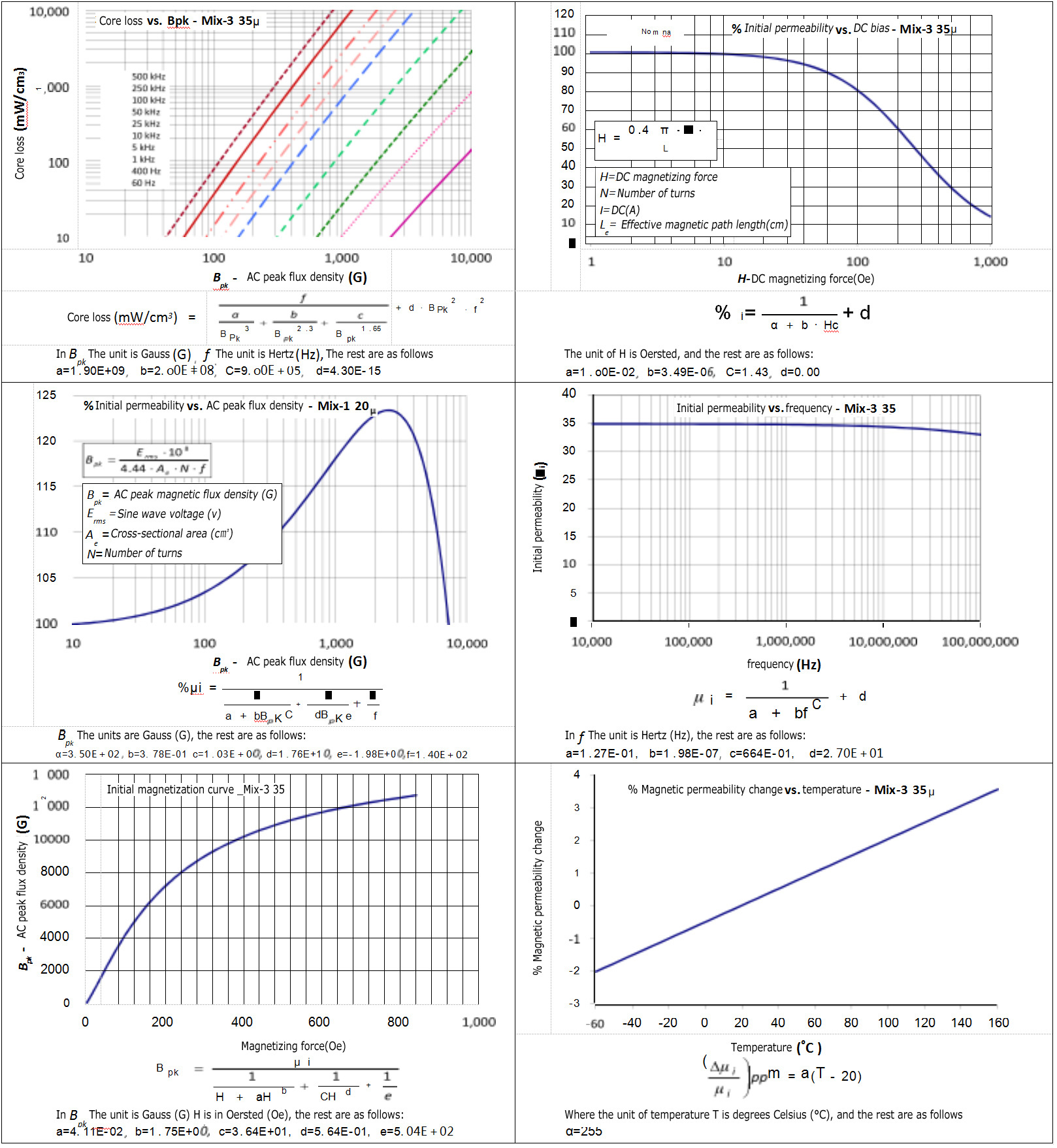

Material No. 3 is annealed carbonyl iron and provides the highest carbonyl permeability. Material No. 3 is suitable for high frequency applications below 1MHz and can also be used in the widest frequency band transformers, with typical coverage between 50~500MHz.

| Mix: | -3 |

i (reference value) | 35 |

color | gray/transparent |

density | 6.5 g/cm³ |

Bsat | 17.6kG |

Core loss (100kHz, 140g) | 31 mW/cm³ (nom) 36 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 60.1%(nom) 53.7% (min) |

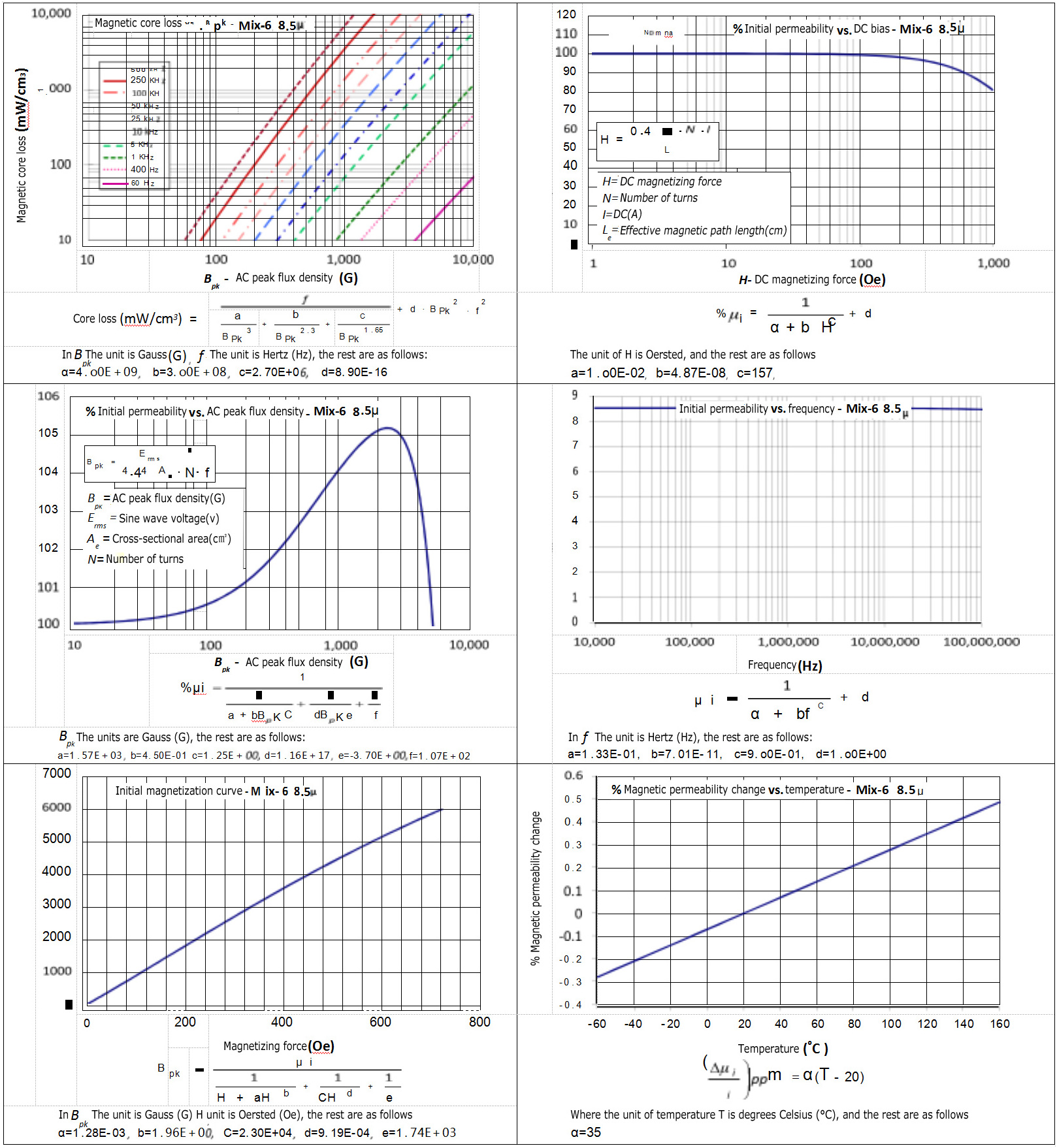

Material -6 is a carbonyl iron mixture and is widely used. Its high Q-factor up to 40MHz makes it popular for amateur radio and various other communications applications. -6 material can also be used for medium-band transformers in the frequency range of 200~400MHz.

| Mix: | -6 |

i (reference value) | 8.5 |

color | yellow/transparent |

density | 5.0 g/cm³ |

Bsat | 14.8kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 98.1%(nom) 97.4% (min) |

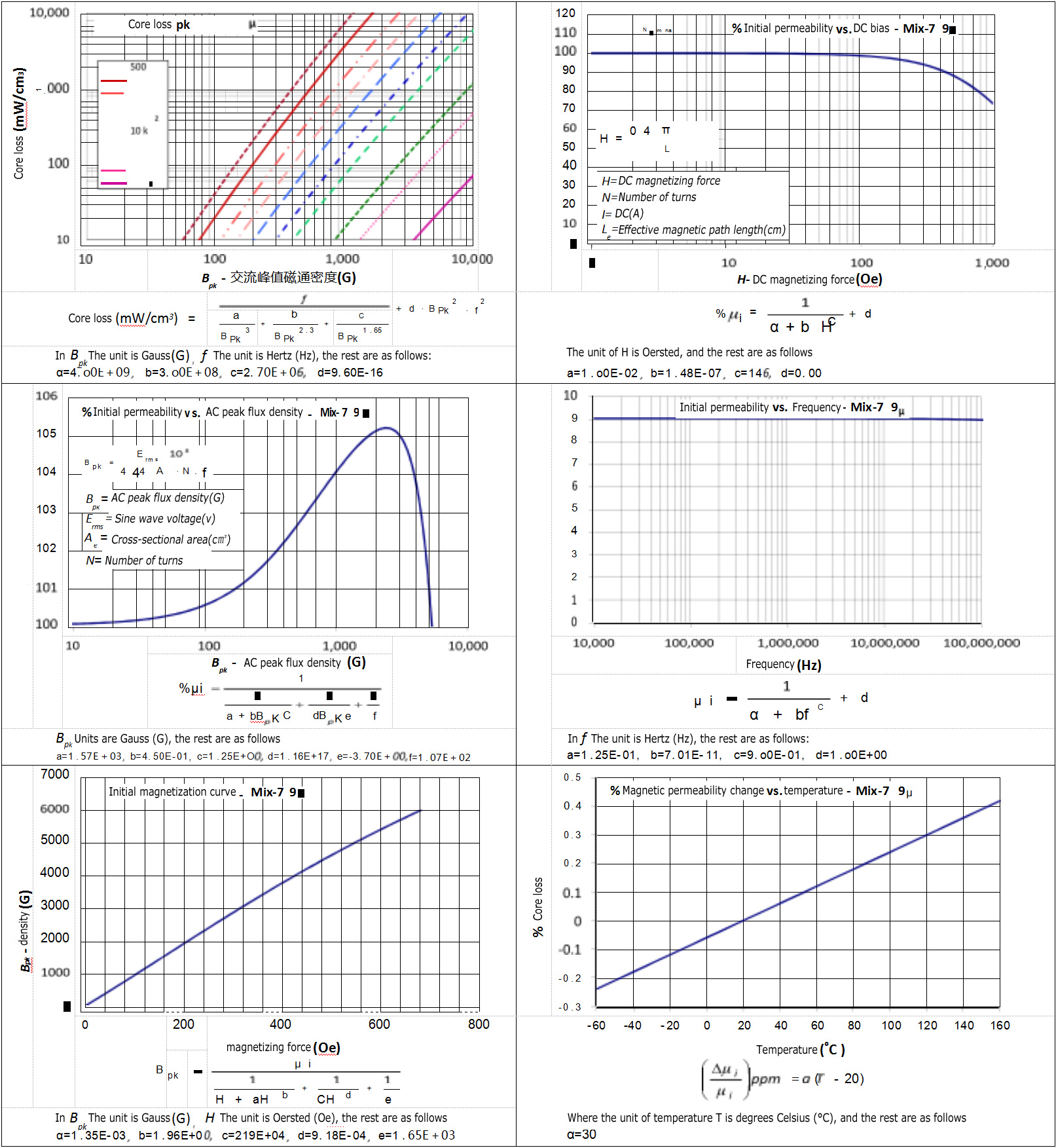

Material No. 7 is a carbonyl iron mixture and is widely used. Its high Q value is up to 40MHz, making it popular for amateur radio and various other communications applications. Material No. 7 can also be used for medium-band transformers in the frequency range of 200~400MHz.

| Mix: | -7 |

i (reference value) | 9 |

color | white/transparent |

density | 5.0 g/cm³ |

Bsat | 14.8kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 96.7%(nom) 95.7% (min) |

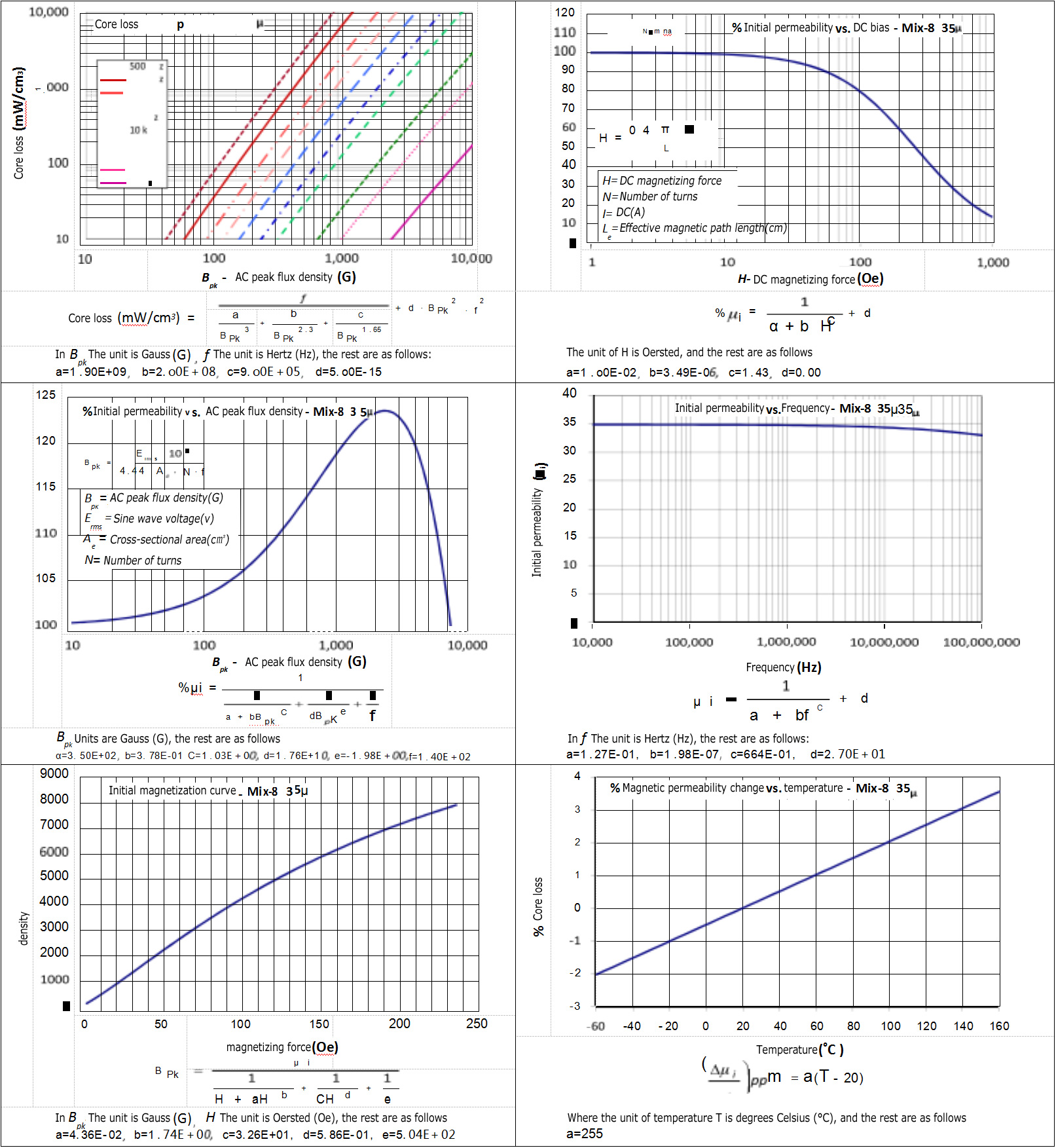

Material -8 is annealed carbonyl iron and provides the highest carbonyl permeability. It is suitable for high frequency applications below 1MHz and can also be used in the widest frequency band transformer, with typical coverage between 50~500MHz. -8 material provides low core losses and good linearity under high current bias conditions. This is a good high-frequency material and the most expensive iron powder material.

| Mix: | -8 |

i (reference value) | 35 |

color | yellow/red |

density | 6.5 g/cm³ |

Bsat | 17.6kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 98.1%(nom) 97.4% (min) |

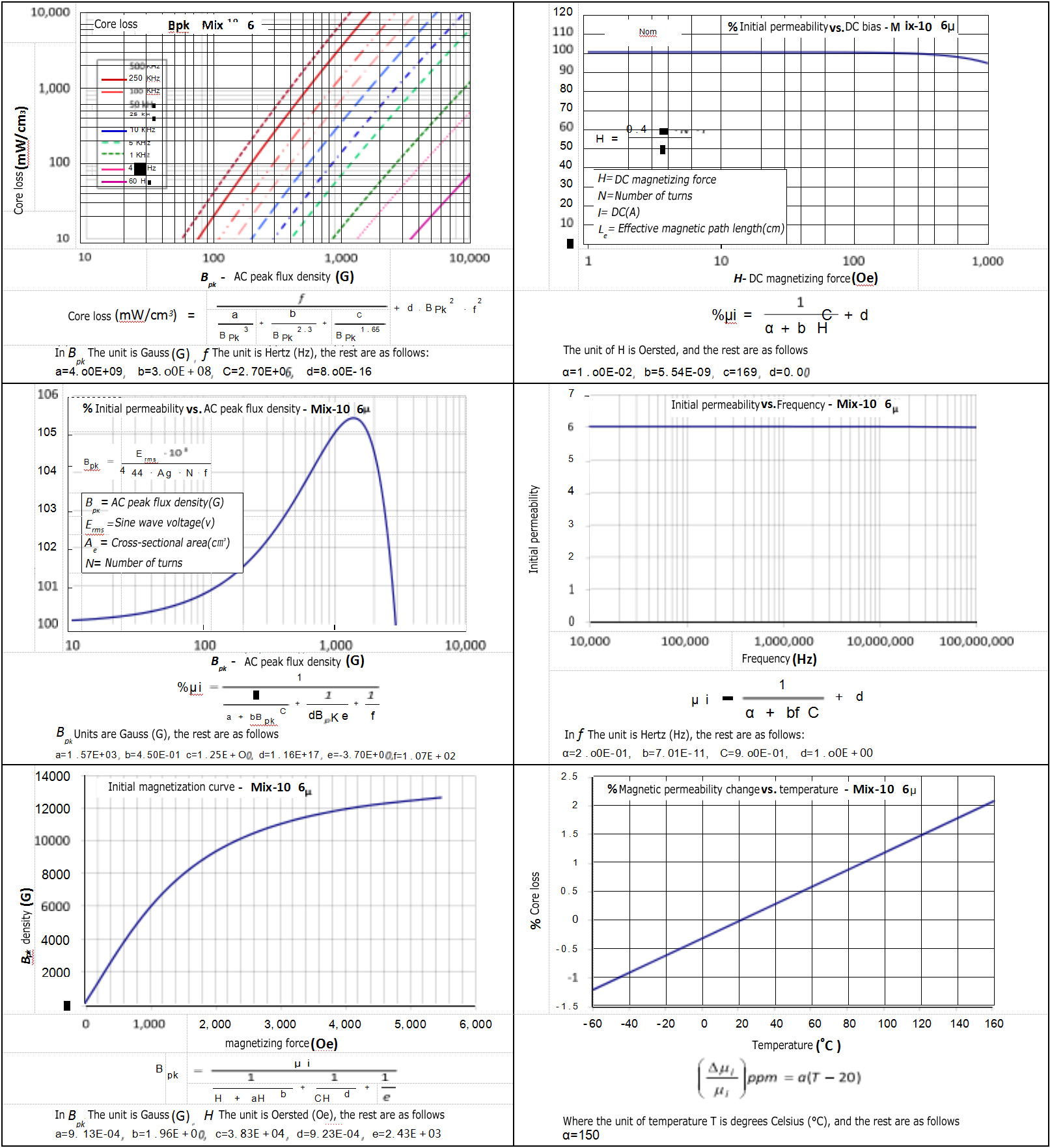

Material No. 10 is carbonyl iron with high-frequency characteristics. Its high Q value reaches 150MHz. It is usually used in cable TV parts and can also be used to produce medium-band transformers of 400~700MHz.

| Mix: | -10 |

i (reference value) | 6 |

color | black/transparent |

density | 4.9 g/cm³ |

Bsat | 14.6kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 99.6% (nom) 99.4% (min) |

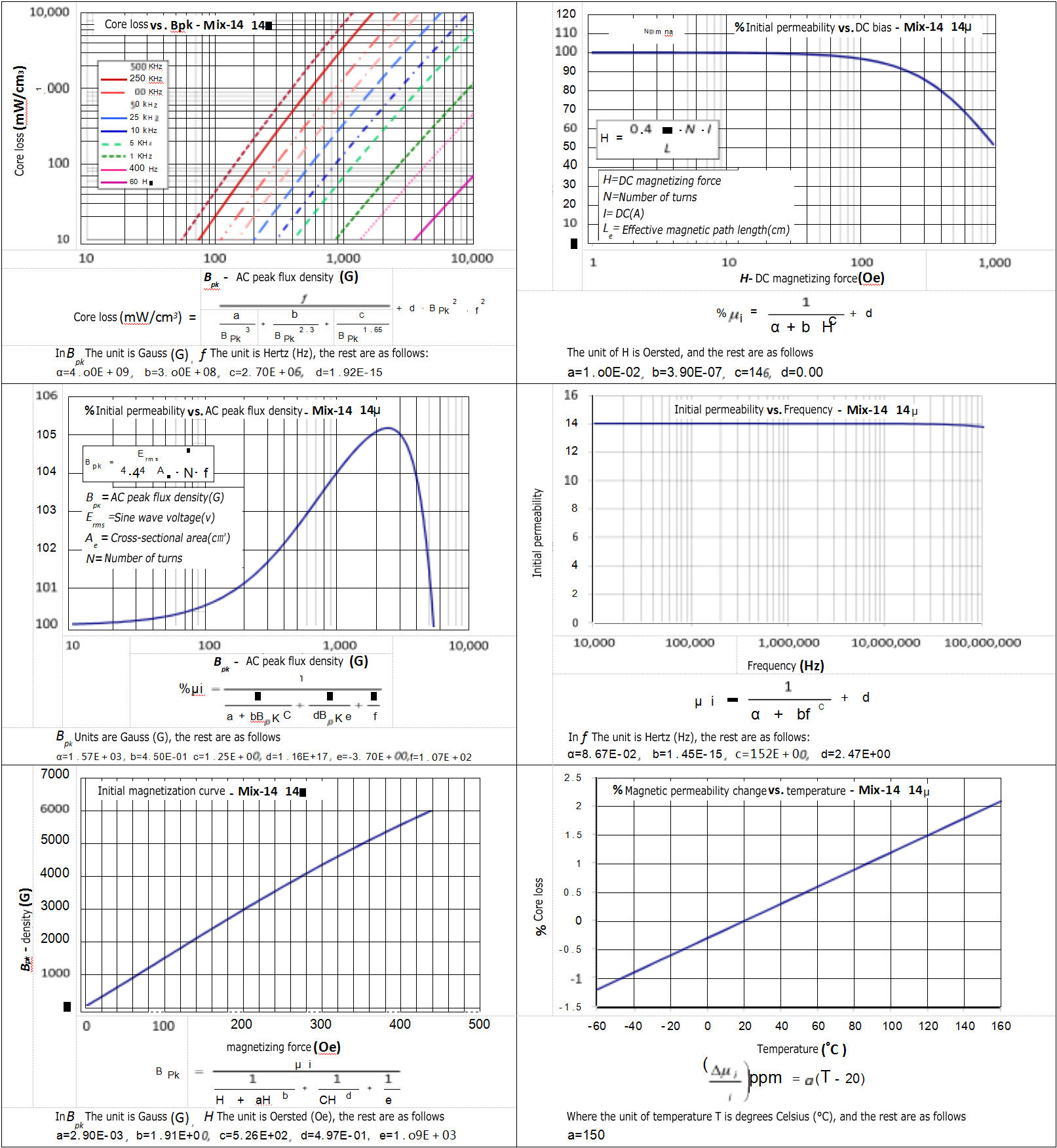

The low permeability of -14 material will result in lower operating AC flux densities than other materials without additional gap losses. -14 material is similar to -2 material, with higher magnetic permeability.

| Mix: | -14 |

| μ i (reference value) | 14 |

color | black/red |

density | 5.2 g/cm³ |

Bsat | 15.2kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 21 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 91.8%(nom) 89.6% (min) |

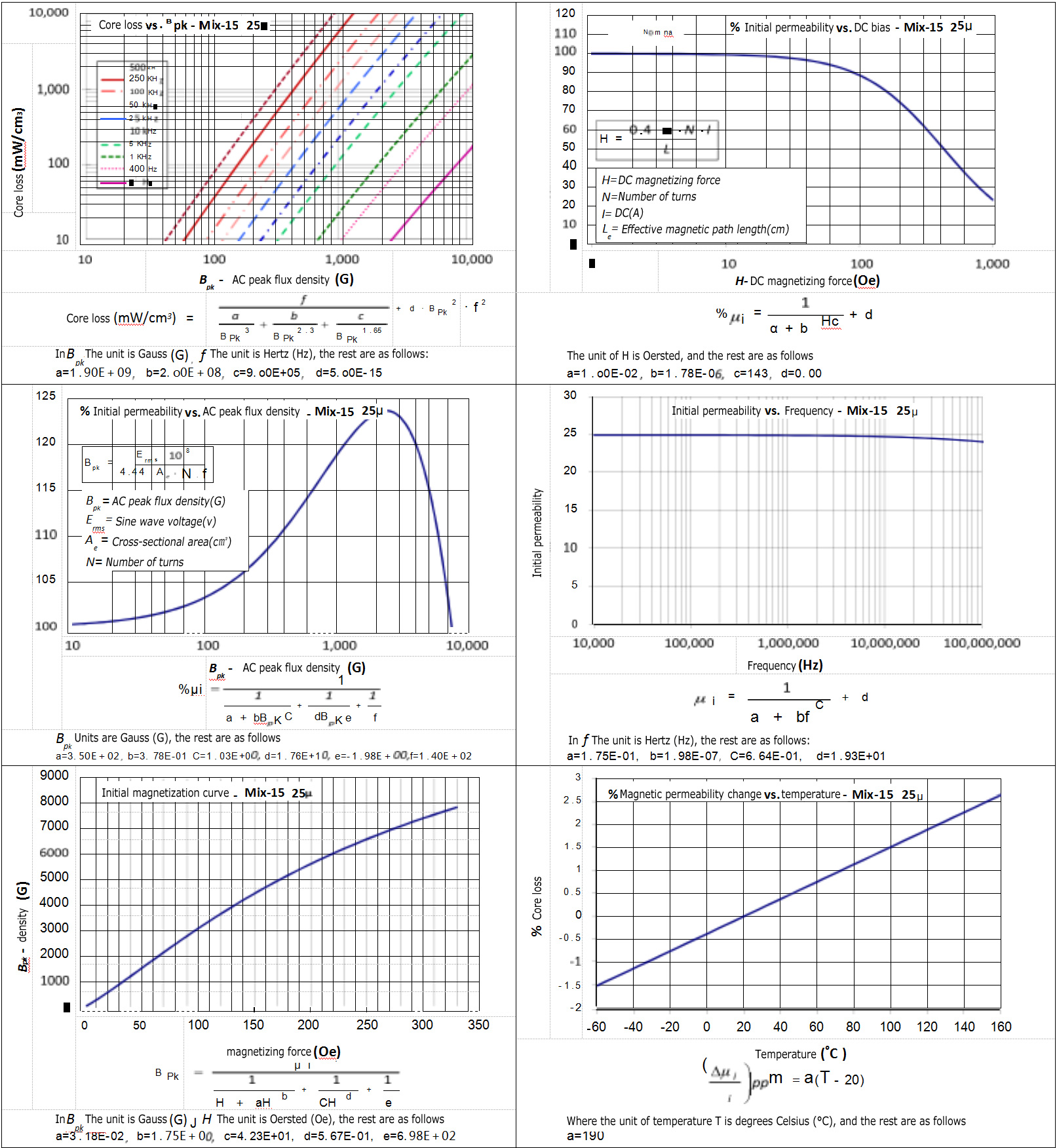

Material -15 is annealed carbonyl iron and provides the highest carbonyl permeability. It is suitable for high frequency applications below 1MHz and can also be used to manufacture the widest frequency band transformers, with its typical coverage range between 50~500MHz.

| Mix: | -15 |

i (reference value) | 25 |

color | red/white |

density | 6.4 g/cm³ |

Bsat | 17.5kG |

Core loss (100kHz, 140g) | 32 mW/cm³ (nom) 36 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 74.7%(nom) 69.4% (min) |

Material No. 17 is carbonyl iron with high-frequency characteristics. Its high Q value reaches 150MHz. It is usually used in cable TV parts and can also be used to produce medium-band transformers of 400~700MHz.

| Mix: | -17 |

i (reference value) | 4 |

color | blue/yellow |

density | 4.8 g/cm³ |

Bsat | 14.4kG |

Core loss (100kHz, 140g) | 18 mW/cm³ (nom) 20 mW/cm³ (max) |

| % Permeability at DC Bias (200 Oe) | 99.5%(nom) 99.4% (min) |